-

BALLAST WATER TREATMENT

BALLAST WATER TREATMENT

SYSTEM DESIGNVIEW PROJECT -

TURN KEY SOLUTION FOR BALLAST

TURN KEY SOLUTION FOR BALLAST

WATER TREATMENT SYSTEM RETROFTTINGVIEW PROJECT -

REFINED RETROFIT PROCESS

REFINED RETROFIT PROCESS

& TECHNOLOGY SELECTIONVIEW PROJECT -

COST EFFECTIVE SOLUTIONVIEW PROJECT

COST EFFECTIVE SOLUTIONVIEW PROJECT -

PROJECT MANAGEMENT &

PROJECT MANAGEMENT &

PLANNINGVIEW PROJECT -

ENSURING IMO REGULATORY

ENSURING IMO REGULATORY

COMPLIANCEVIEW PROJECT

BWTS RETROFIT PHASES

examination of documents

- Vessel Ballast P&ID

- Investigate Existing BWMS

- Machinery Arrangement drawings

- Electrical drawings

Design and Detailed Engineering

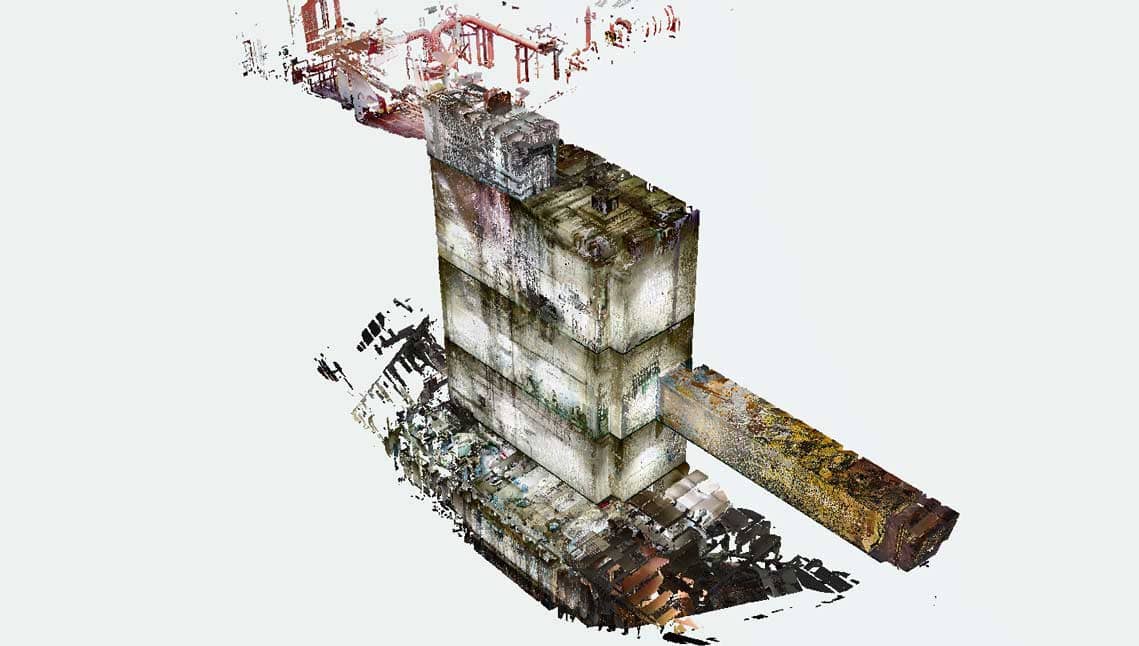

3D Scanning & On-Board Survey

- BWTS Location identification

- Examination of Tie in

- Electrical Compatibility

- Discussion of Key aspects of BWTS installation

Approval

Feasibility Study & Basic Engineering

- Ballast System Piping Schematic

- Conceptual pipe routing

- Electric Load Analysis

- Ancillary Considerations

- Technology Selection

Fabrication

- Project Management

- Weldments

- Pre-fabrication of pipe Spools

- Pipe Support

- Foundation Structure

Installation & Commissioning

REFINED PROCESS

To design and install a Ballast Water treatment system into an as- build vessel is a rigorous process. Based on the experience and the knowledge gained, Oshiana carefully developed a refined process flow for integrating the Ballast Water treatment system into the existing vessels. Each element in the above phases is inevitable while designing and installing the BWTS into the vessels.

SKID DESIGN

Skid version is needed mainly for new build vessels:

All components and the filter can be mounted on to the platform

The control cabinet can be mounted or separated from the skid depends up to the ground situation.

Provide compact design to adapt the available space in the vessel.

Provide compact design to adapt the available space in the vessel.

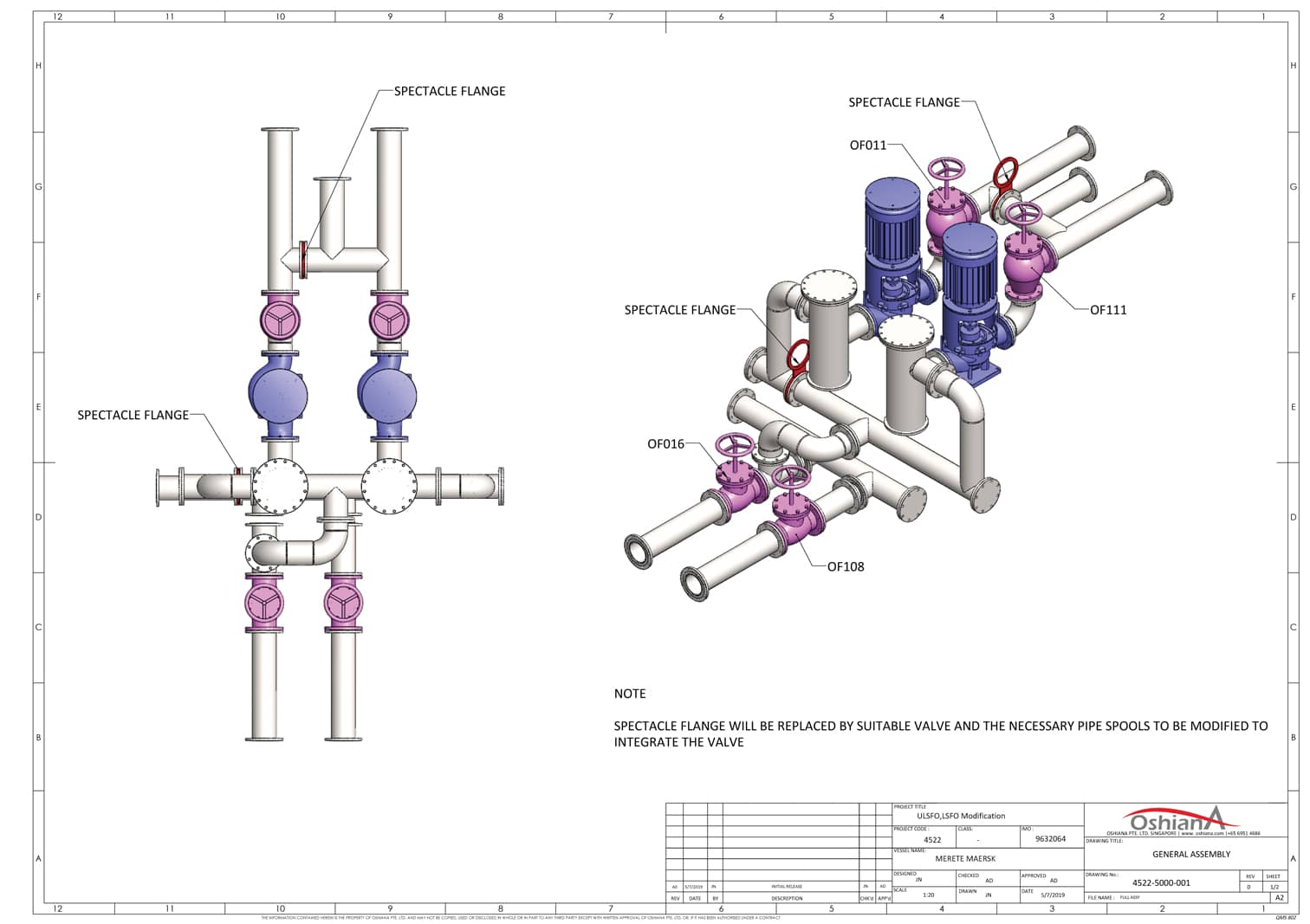

Design & Detail Engineering

Accuracy of the design determines the competency of the remaining process of the ballast water treatment system integration, where on the basis of preliminary study and conceptual modelling, Oshiana’s BWTS design experts guarantee a highly precise design and detail engineering to our clients by using the specialized software in the given time frame. Design and detail engineering is a predominant phase in the process flow of integrating Ballast water treatment system into the existing vessels and has a strong impact on the overall cost of this process where Oshiana provides a cost-effective design and detail engineering with excellent quality as our clients expect. Our Design & Detailed Engineering package will commence subject to the approval of conceptual modelling. Oshiana will work closely with BWTS maker and vessel owner to achieve the deliverables on time.

Read More3D Laser scanning & survey

We are dedicated to work hard and smart and believe that the result

we achieve are the only valid measure of our success.

We believe the foundation of our business rest on honesty responsibility and our action. We value and understand the importance of transparency and always fulfill our promises to customer and stakeholder.

BWTS Retrofit

Oshiana has an experienced project management team for the project planning and to install Ballast water treatment system (BWTS) Plant while vessel at In-Service / Dy Dock. All the essential pipe spools are pre-fabricated and assembled on the site.

Mechanical Installation

Electrical Installation

Pre-commissioning

EGCS retrofit

IMO regulations to reduce sulphur oxides (SOx) emissions from ships first came into force in 2005, under Annex VI of the International Convention for the Prevention of Pollution from Ships (known as the MARPOL Convention). Since then, the limits on sulphur oxides have been progressively tightened.

Read MoreFeasibility Study

Based on the survey details and the 3D scan data captured, Oshiana will perform a feasibility study, where we assess the practicality of installing a BWTS (Ballast water treatment system) into the existing vessel and recommend a suitable BWT system for that vessel. Oshiana’s evaluation process is on the basis of the BWTS equipment Footprint, Power consumption, Treatment rated capacities (TRC), Holding Time, Stripping operation, Consumable required, Filter pressure drop etc.After the completion of the evaluation process, Basic engineering will commence by using the selected technology for the vessel.

Read MoreFabrication

Oshiana has a track record of fabricating pipe spool for BWTS retrofitting. We are competent to provide optimised solution for fabrication as per marine standard. Pipe spool and associated components/steel structures are pre-fabricated by our local partner in Singapore in a cost effective way and it can be shipped to the desired location/site for the installation. BWTS retrofit guide for the installation of pre-fabricated spools will be provided.

Read More

SKID DESIGN

Design & Detail Engineering

3D Laser scanning & survey

BWTS Retrofit

EGCS retrofit

Feasibility Study

Fabrication

WHO WE ARE?

INTEGRITY

Oshiana, We are a group of Design Engineers who are highly skilled to do the ballast water treatment system, which is our core business. Our advantage is to take the decision immediately after analyzing the situation as we are proficient to identify the actual engineering challenge in this field. We believe the foundation of our business rest on honesty, responsibility and our action. We value and understand the importance of transparency and always fulfil our promises to our customers and stakeholders on time. We uphold the highest standards of integrity in all of our actions and to put forth a great and tenacious effort to prevent any violation of engineering ethics.

COMMITMENT

Oshiana, We are a group of Design Engineers who are highly skilled to do the ballast water treatment system, which is our core business. Our advantage is to take the decision immediately after analyzing the situation as we are proficient to identify the actual engineering challenge in this field. We believe the foundation of our business rest on honesty, responsibility and our action. We value and understand the importance of transparency and always fulfil our promises to our customers and stakeholders on time. We uphold the highest standards of integrity in all of our actions and to put forth a great and tenacious effort to prevent any violation of engineering ethics.

QUALITY

We are dedicated to work hard and smart and believe that the result

we achieve are the only valid measure of our success.

We believe the foundation of our business rest on honesty responsibility and our action. We value and understand the importance of transparency and always fulfill our promises to customer and stakeholder.

ETHICS

We are dedicated to work hard and smart and believe that the result

we achieve are the only valid measure of our success.

We believe the foundation of our business rest on honesty responsibility and our action. We value and understand the importance of transparency and always fulfill our promises to customer and stakeholder.

-

INTEGRITY

-

COMMITMENT

-

QUALITY

-

ETHICS

Regulation

The International Convention for the Control and Management of Ships’ Ballast Water and Sediments, 2004 (BWM Convention), came into force in September 2017. To date, it has been ratified by 79 countries, collectively representing 80.94% of the world’s merchant shipping tonnage. Under this convention, all types of ships, including submersibles, floating craft/platforms, FSUs, and FPSOs, are obligated to manage their ballast water in compliance with an approved Ballast Water Management Plan. Additionally, they must diligently record their ballast water management activities in a Ballast Water Record Book, adhering to the Convention’s provisions. This adherence is based on the following implementation schedule

References

Oshiana boasts extensive experience in managing BWTS for various types of vessels, encompassing container carriers, bulk carriers, oil and chemical tankers, cruise ships, and LNG carriers.

Furthermore, Oshiana excels in the implementation of diverse technologies, including Electrochlorination, UV systems, Ozone treatment, and Electro-catharsis BWT Systems.

NEWS FEED

Our construction managment professionals organize, lead and manage the people, materials and processes of construction utilizing the latest technologies within the industry.

Testimonial 1

Our construction managment professionals organize, lead and manage the people, materials and processes of construction utilizing the latest technologies within the industry.

Testimonial 2

Our construction managment professionals organize, lead and manage the people, materials and processes of construction utilizing the latest technologies within the industry.

Testimonial 3

Our construction managment professionals organize, lead and manage the people, materials and processes of construction utilizing the latest technologies within the industry.

Testimonial 4

our

partners

Accuracy of the design determines the competency of the remaining process of the ballast water treatment system integration, where on the basis of preliminary study and conceptual modelling, Oshiana’s BWTS design experts guarantee a highly precise design and detail engineering to our clients by using the specialized software in the given time frame. Design and detail engineering is a predominant phase in the process flow of integrating Ballast water treatment system into the existing vessels and has a strong impact on the overall cost of this process where Oshiana provides a cost-effective design and detail engineering with excellent quality as our clients expect. Our Design & Detailed Engineering package will commence subject to the approval of conceptual modelling. Oshiana will work closely with BWTS maker and vessel owner to achieve the deliverables on time.

Oshana’s Design & Detailed engineering inclusive of:

- Class submission documents.

- Ballast water treatment System (BWTS) Piping Design.

- Foundation Structure Design / Modifications.

- Electrical compatibility.

- Pressure drop calculation.

- Flow analysis Before & After BWTS.